Manufacturing

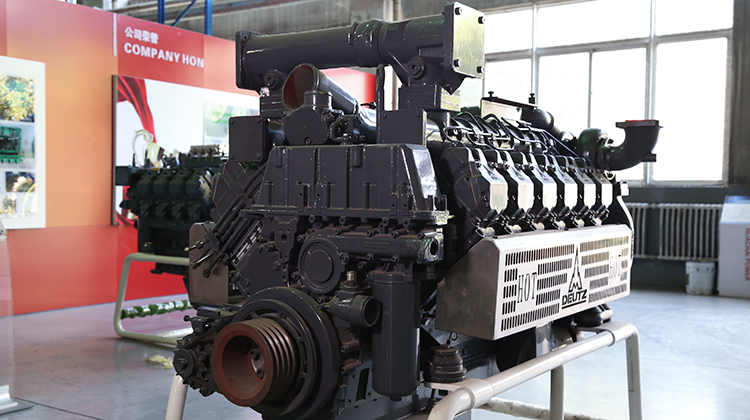

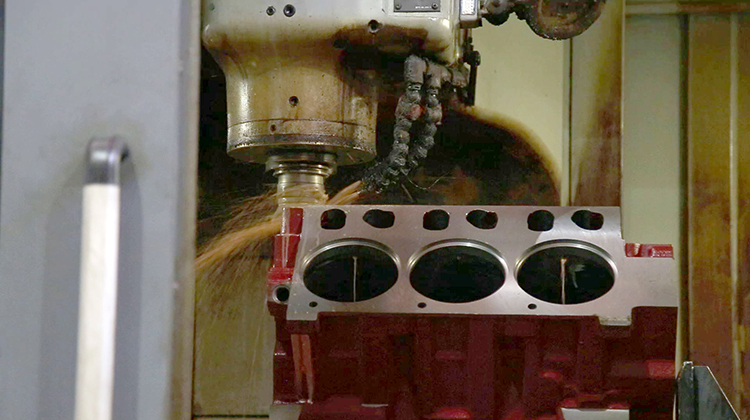

Huachai Power operates two crankcase production lines, a water-cooled diesel engine crankcase production line and an air-cooled diesel engine crankcase production line. They are outfitted with thirty CNC machining centers and other exclusive production equipment.

In the first machine workshop, there are two production lines: the water-cooled diesel engine cylinder head production line and water-cooled diesel engine crankshaft production line. In the workshop, there are seven machining centers and exclusive machines, supporting a production of 72 pcs in a single day.

The second machine workshop is focused on the production of diesel engine spare parts, such as piston pins, intake pipes, steel belt pulleys and intermediate shafts.

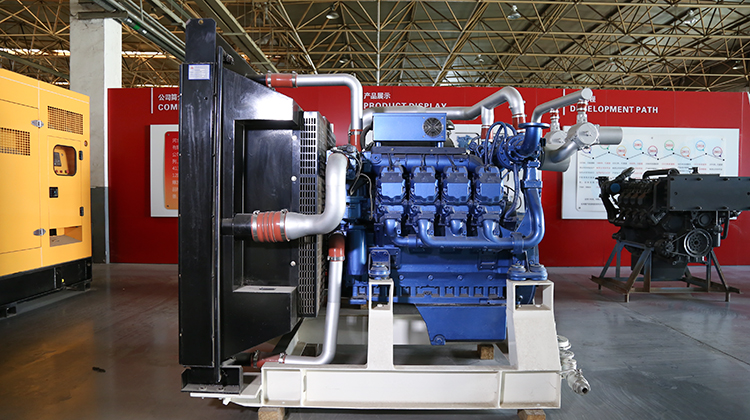

As for our ultra-efficient assembly line, we have adopted a linear propulsion method and 9 workstations, perfectly satisfying the mixed model assembly of V6, V8 and V12 air-cooled or water-cooled diesel engines. Meanwhile, the assembly line provides a daily assembling of 15 diesel engines.

HUACHAI POWER has two air-cooled testing stations and eleven water-cooled testing stations, which are responsible for the research and testing for our diesel engines.

Norinco Huachai Power’s crankcase manufacturing factory has two crankcase production lines, water-cooled diesel engine crankcase production line and air-cooled diesel engine crankcase production line. They are outfitted with thirty CNC machining centers and exclusive equipment.

In the first machining workshop, there are two production lines: water-cooled diesel engine cylinder head production line and water-cooled diesel engine crankshaft production line.

Crankcase manufacturing factory

Crankcase manufacturing factory  Full view of the first machining workshop

Full view of the first machining workshop

Second machining workshop is involved in the production of diesel engine spare parts, such as piston pins, intake pipe, steel belt pulley and intermediate shaft.

Full view of the second machining workshop

Full view of the second machining workshop Machining center

Machining center

First machining workshop is equipped with seven machining centers and exclusive machines, supporting a production of 72 diesel engines in a single day.

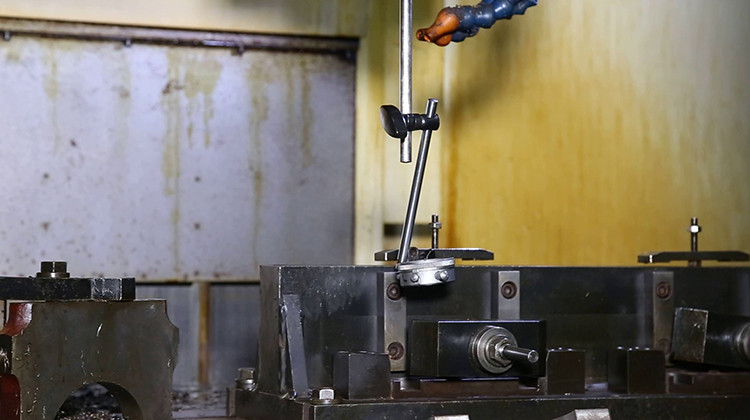

CNC lathe

CNC lathe  Close-up for machining zone

Close-up for machining zone  Cylinder linear machining center

Cylinder linear machining center Close-up for machining zone

Close-up for machining zone

Not only the production of diesel engine spare parts manufacturing, second machining workshop is also responsible for the commissioning of injection pump and injection timing, as well as the production and repair for workpieces and nonstandard products.

Machining line

Machining line Close-up for cutting zone

Close-up for cutting zone

Assembly line

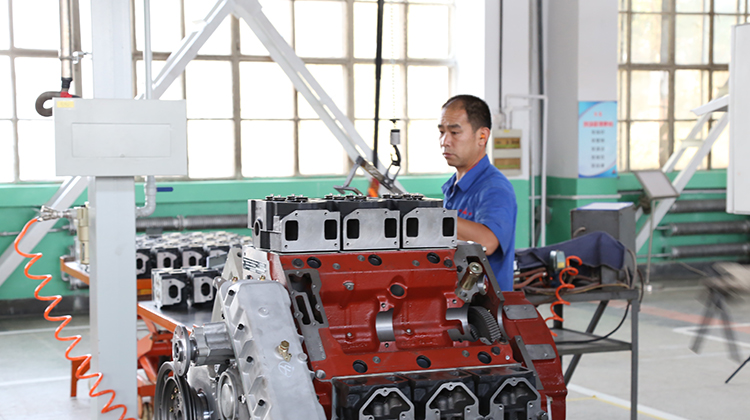

Assembly factory covers an overall area of 9,960 square meters, which could be divided into assembly workshop and testing rooms.

Assembly line could be divided into four separate zones, mainly involved in the assembly for V6 diesel engine, V8 diesel engine, V12 diesel engine and water-cooled diesel engine.

First assembly zone

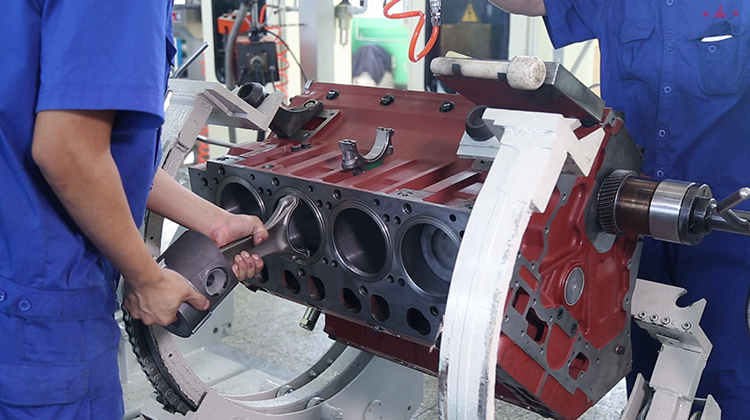

First assembly zone  Installing for piston

Installing for piston

The linear assembly line is rail propelled, which is equipped with nine workstations in an area of 100 meters’ length. Foldable trollies are introduced for the transportation, well satisfying the mixed assembling requirements towards V6 diesel engine, V8 diesel engine, V12 diesel engine and water-cooled diesel engine. The line could perfectly support a daily assembly of 15 diesel engines when there is no shift.

Fastening for key components

Fastening for key components Key component testing

Key component testing

All the key components of diesel engine, such as the main bearing cap bolt, connecting rod bolts, flywheels, crankshaft pulley bolts, cylinder head bolts and so on, are all fastened by CNC bolt tightening machine. In addition, a comprehensive series of testing instrument, including feeler gauge, ignition timing tester, and air tightness testing machine and etc., are all involved in our production line, well ensuring the high quality of our products.

Manual fastening for diesel engines

Manual fastening for diesel engines

Cleaning unit is mainly responsible for the cleaning of some engine parts, and painting unit is mainly involved in the cleaning, painting and drying for whole diesel engines.

Cleaning unit

Cleaning unit Painting unit

Painting unit

Norinco Huachai Power has thirteen testing rooms, including two air-cooled testing rooms and eleven water-cooled rooms, which are in charge of the research and testing for our diesel engines.

Full view of testing room

Full view of testing room Real-time testing system

Real-time testing system

Hebei Huabei Diesel Engine Co.,ltd.

Add.: P.O. 910,Zhongshan West Road , Shijiazhuang, Hebei, China.

Contact: Jack

Fax: +86-10-63843710